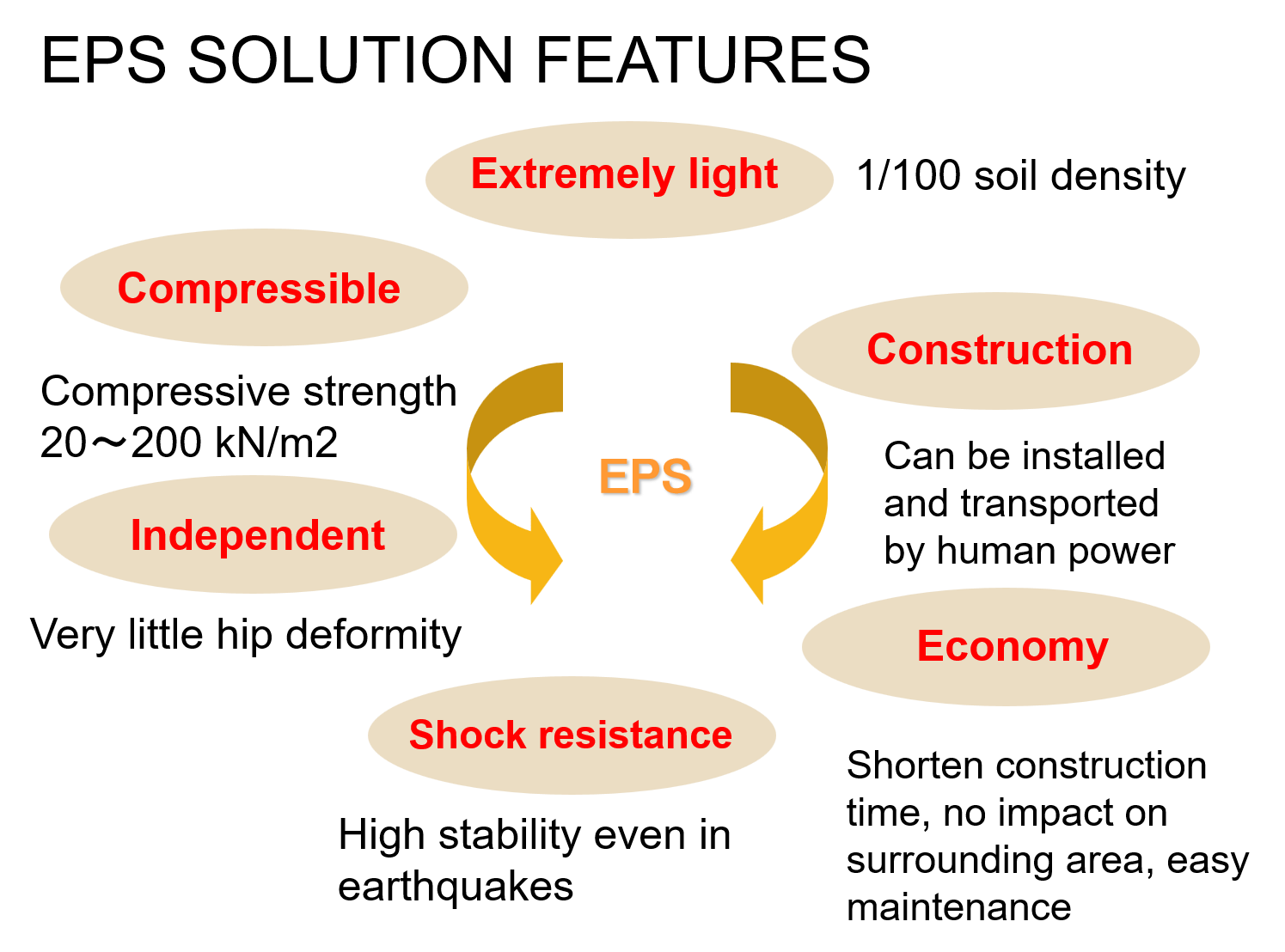

EPS SOLUTION INTRODUCTION

EPS (Expanded Polystyrene) Solution

With the characteristics of lightweight materials with a volumetric mass of about 1 - 70% compared to soil or rock. Therefore, there are many different types of lightweight materials used, including compressible materials such as: Styrofoam, foam concrete and granular materials such as furnace slag, ash, expanded ceramics... Currently, the most commonly used material is expanded polystyrene foam, with the advantages of being easy to process, preserve and having a low volumetric mass. In particular, lightweight material EPS (Expanded Polystyrene) has a volumetric mass of only 1% ~ 2% compared to soil, rock or concrete, and can withstand large compressive stress. Therefore, using EPS as a filling material for light-weight constructions does not require foundation treatment by methods such as: Preloading, lime-soil pillars, cement... This reduces costs and construction time.

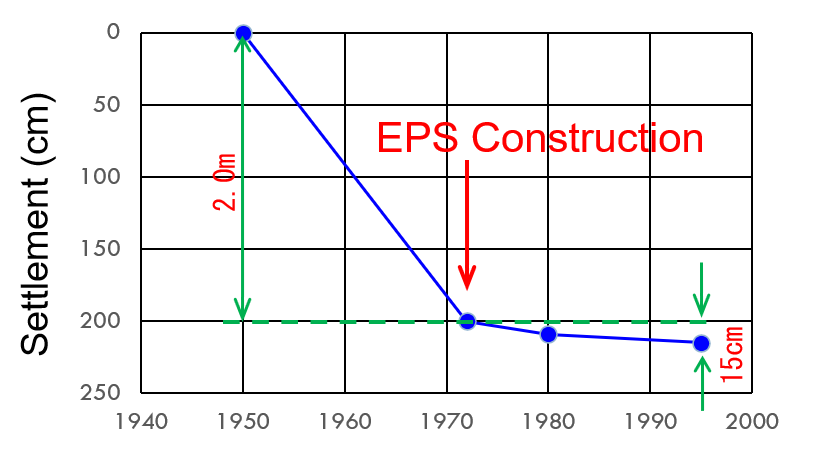

EPS solution was first applied in 1972 in Norway, Geofoam blocks made of Expanded Polystyrene (EPS) were produced for the purpose of filling material, light weight (see picture below), reducing earth pressure and some other applications in construction, the solution has been applied and developed in many countries around the world.

|  |

EPS construction to prevent settlement of roadbed in Oslo, Norway, 1972

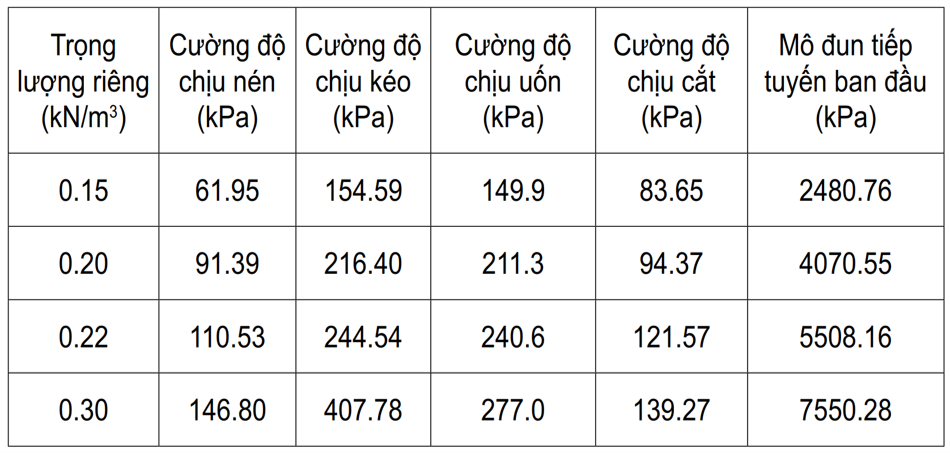

EPS material is very light and can be produced in many shapes with very low specific gravity, g = 0.12 - 0.35 kN/m3 (about 1/100 compared to soil). Geofoam blocks used for construction and traffic works are usually 0.5×1.0×2.5 - 3.0 m in size, weighing 25 - 30 kg. According to the publication of Aabøe et al. and Padade A. H. et al., the strength of EPS material varies linearly with the specific gravity of the material.

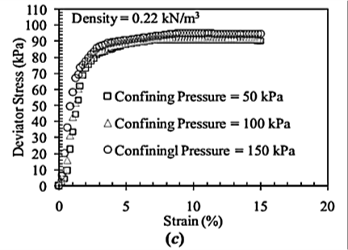

The table shows the mechanical properties of EPS.

The table shows the mechanical properties of EPS.

|  |

|  |

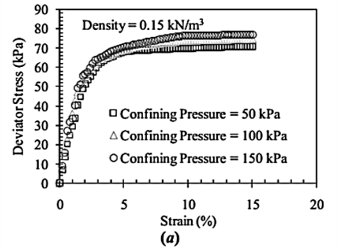

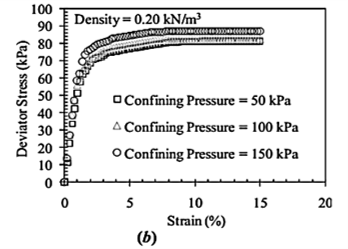

Figure: Stress-strain relationship of EPS from triaxial compression results for different specific gravity

With the characteristics of waterproof, almost no water absorption, constant density and properties due to water, little side deformation when loaded, light material, convenient for construction, no need for compaction and compaction management, applied in conditions where large-sized machinery cannot be used, short construction time.

Currently, EPS solutions have been used in many countries around the world, especially European countries such as: Czech Republic, Germany, Greece, Netherlands, Norway, Poland, Serbia, Sweden, UK ... successfully applied in the field of construction of traffic works and civil construction. In Asia, many countries have also successfully applied EPS solutions in construction such as Japan, China, Malaysia, Thailand, Philippines, Korea and Taiwan, India.... .

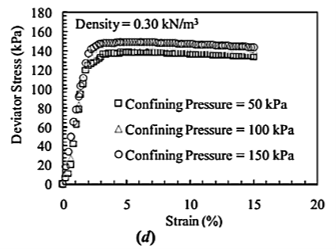

Image of using EPS for roadbed construction in Sapporo, Japan

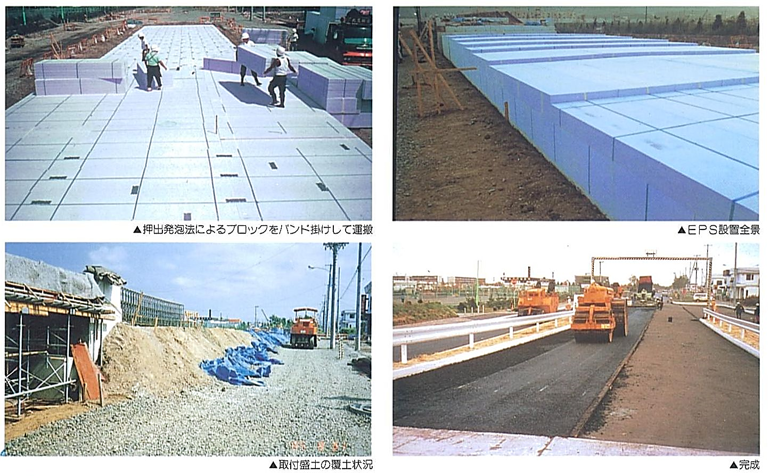

Figure: Actual application of EPS solution in Japan (Refer to statistics of OKLSLN LIVIC CO, LTD)

The figure above shows the data on the use of EPS in construction in Japan from 1986 to the end of 2017. It is seen that the cumulative volume of EPS used in Japan increased linearly over time, demonstrating the effectiveness of EPS in construction.

EPS solution for construction on weak soil can be summarized through the following construction steps:

- Site preparation (Figure a);

- Equipment and EPS block installation (Figure b);

- Reinforcement installation and concrete pouring (Figure c);

- Finishing (Figure d).

|  |

Figure a. Construction site preparation work

|  |

Figure b. Installation of equipment and EPS block

|  |

Figure c. Installation of reinforcement and pouring of concrete

|  |

Figure d. Finished

Excerpt: Bridge and Road Magazine No. 4, 2020

vi

vi